Introduction:

The Van der Pauw method is a technique for measuring the electrical

resistivity and carrier mobility of a semiconductor material. The method was

developed by L.J. van der Pauw in 1958 and is widely used in materials science

and engineering.

The method involves measuring the electrical resistance of a sample

using four probe contacts arranged in a square or rectangular configuration.

The contacts are made on opposite sides of the sample, and the resistance is

measured using a multimeter. The sample is then rotated by 90 degrees, and the

resistance is measured again. By repeating these measurements for different

configurations of the four-probe contacts, the electrical resistivity of the

sample can be determined.

The Van der Pauw method can also be used to determine the carrier

mobility of a semiconductor material. Carrier mobility is a measure of how

easily charge carriers (electrons or holes) move through the material under the

influence of an electric field. To measure the carrier mobility, the sample is

subjected to a magnetic field perpendicular to the sample surface, and the

electrical resistance is measured as before. By repeating the measurements for

different magnetic field strengths and orientations, the carrier mobility can

be calculated using the Hall effect equation.

Overall, the Van der Pauw method is a simple and accurate technique

for measuring the electrical resistivity and carrier mobility of semiconductor

materials. It is commonly used in research and industry for quality control and

performance optimization of semiconductor devices.

Hall effect measurement:

The Hall effect is a phenomenon in which a magnetic field applied

perpendicular to a current-carrying conductor induces a voltage across the

conductor in the direction perpendicular to both the magnetic field and the

current. This effect was discovered by American physicist Edwin Hall in 1879.

Hall effect measurements are used to determine the electrical

properties of materials, particularly their carrier concentration, mobility,

and type (whether they are electrons or holes). In a Hall effect measurement, a

sample of the material is placed in a magnetic field, and a current is passed

through the sample in a direction perpendicular to both the magnetic field and

the voltage that develops due to the Hall effect. By measuring the voltage

across the sample and the current passing through it, the carrier concentration

and mobility can be determined using the Hall effect equation.

The Hall effect measurement can provide valuable information about

the electronic properties of materials, which is important in many applications

such as semiconductor device design, material characterization, and quality

control. For example, in semiconductor device design, the Hall effect

measurement can be used to optimize the doping level and thickness of the

semiconductor layers to achieve the desired electrical performance. In material

characterization, the Hall effect measurement can be used to determine the

effect of impurities and defects on the electrical properties of the material.

Sample preparation:

Ohmic contacts are formed on the sample surface in a preferred way following ways figure 1:

Figure1: Van der Pauw method sample required

Overall, the Hall effect measurement is a powerful tool for

understanding the electrical properties of materials and has many practical

applications in industry and research.

What is Hall voltage and quantized Hall voltage?

The Hall voltage is the voltage that develops across a sample of a conducting material when a magnetic field is applied perpendicular to the flow of electrical current through the sample. The Hall voltage is proportional to the applied magnetic field, the current through the sample, and the carrier concentration and mobility of the charge carriers in the material. Figure 2 is the Hall measurement setup.

Figure 2: Hall voltage measurement principle

The Hall

voltage is given by the Hall effect equation:

V_H = BIn*q / d

where V_H is the Hall voltage, B is the magnetic field strength, I

is the current passing through the sample, n is the carrier concentration, q is

the charge of the carriers, and d is the thickness of the sample.

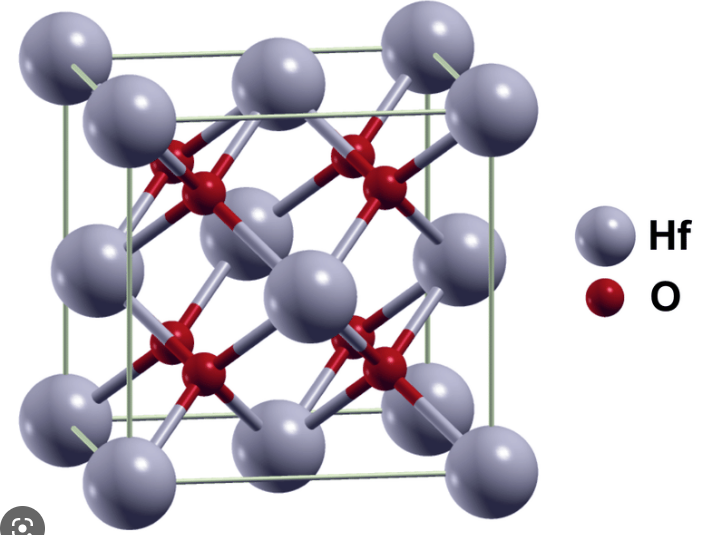

The Van der Pauw configuration is shown in Figure 3.

Figure 3: Van dar Pauw configuration for Hall voltage measurement

Quantized Hall voltage, also known as the integer quantum Halleffect (IQHE), is a phenomenon observed in two-dimensional electron systems in the presence of a strong magnetic field. In this regime, the Hall resistance (the ratio of Hall voltage to current) exhibits quantization at certain values, which are independent of the material properties and the geometry of the sample. The quantized Hall resistance is given by the equation:

R_H = (h/e^2) * (N + 1/2)

where R_H is the Hall resistance, h is Planck's constant, e is the elementary charge, and N is an integer known as the Landau level index.

What is the landau level index?

In condensed matter physics, the Landau level index refers to a quantum

number that characterizes the energy levels of electrons in a two-dimensional

system subjected to a strong magnetic field perpendicular to the plane of the

system. These energy levels are known as Landau levels, and the Landau level

index is a measure of the quantized energy of electrons in a particular Landau

level.

In a strong magnetic field, the electrons in a two-dimensional

system occupy discrete energy levels, known as Landau levels, which are

separated by a constant energy spacing known as cyclotron energy. The

Landau level index, denoted by N, is an integer that specifies the energy level

of an electron in the system, with higher values of N corresponding to higher

energy levels. The energy of each Landau level is given by the equation:

E_N = (N + 1/2) * hbar * omega_c

where E_N is the energy of the Nth Landau level, hbar is the

reduced Planck's constant, and omega_c is the cyclotron frequency, which is

proportional to the applied magnetic field.

The Landau level index plays a crucial role in the phenomenon of

the quantized Hall effect, where the Hall resistance of a two-dimensional

system in a strong magnetic field exhibits quantization at certain values of

the magnetic field strength and Landau level index. The quantization of the

Hall resistance arises from the topological properties of the electron wave

function in a magnetic field and is independent of the material properties and

sample geometry.

The quantization of the Hall resistance is a result of the

topological properties of the electron wave function in a magnetic field and

has important implications for the study of condensed matter physics and the

development of novel electronic devices.

Why do we need to measure quantized Hall voltage?

The quantized Hall voltage, also known as the integer quantum Hall

effect (IQHE), is an important phenomenon to study in condensed matter physics

because it provides a unique example of a topological quantum state of matter.

The quantization of the Hall resistance in a two-dimensional electron gas in a

strong magnetic field is independent of the sample geometry, impurities, and

other perturbations, and is determined solely by fundamental constants such as

Planck's constant and the elementary charge. This makes the IQHE an extremely

precise standard for resistance measurement.

The quantized Hall voltage has several practical applications,

especially in metrology, where it is used as a standard for the calibration of

resistance measurement devices. The quantization of the Hall resistance is very

precise, with a relative uncertainty of less than 10E-9, which makes it an

ideal standard for resistance measurements in various fields such as materials

science, electronics, and metrology.

Moreover, the IQHE has led to the discovery of many new phenomena

in condensed matter physics, including the fractional quantum Hall effect,

which is a phenomenon that occurs at lower magnetic fields and involves the quantization

of the Hall resistance at fractional multiples of the standard quantized value.

The study of these effects has led to the development of new theoretical models

and insights into the behavior of electrons in condensed matter systems.

Overall, the measurement of quantized Hall voltage is important

both for fundamental research and for practical applications, especially in

metrology and resistance measurement. Find more diverse field discussions in the home page tabs here.