Introduction:

The Green Energy Mission in semiconductor research field focuses on developing energy-efficient technologies and processes to reduce the environmental impact of semiconductor manufacturing and promote sustainable energy solutions. Semiconductor manufacturing is an energy-intensive process that requires a significant amount of electricity and produces greenhouse gases and other pollutants. The Green Energy Mission seeks to address these environmental concerns by developing new technologies and processes that reduce energy consumption and carbon emissions.

Some of the key areas of research in the Green Energy Mission include:

Energy-efficient semiconductor manufacturing: Researchers are developing new techniques to reduce energy consumption and carbon emissions in semiconductor manufacturing, such as using renewable energy sources, optimizing manufacturing processes, and developing energy-efficient devices.

Renewable energy: Semiconductors play a critical role in renewable energy systems, such as solar panels and wind turbines. Researchers are working to improve the efficiency and reduce the cost of these systems to promote widespread adoption.

Energy storage: Semiconductor devices are used in energy storage systems, such as batteries and capacitors. Researchers are developing new materials and processes to improve the performance and reduce the environmental impact of these systems.

Energy harvesting: Researchers are developing semiconductor-based technologies to harvest energy from renewable sources, such as solar and kinetic energy, to power small devices and sensors.

Overall, the Green Energy Mission in semiconductor research aims to develop sustainable and energy-efficient technologies that promote environmental sustainability and reduce the dependence on fossil fuels.

Yes, here is a list of some of the commonly used power semiconductor materials:

Semiconductor materials:

Silicon (Si): Silicon is the most widely used material for power semiconductor devices due to its abundance, low cost, and excellent electrical properties. It is used in devices such as diodes, thyristors, and insulated gate bipolar transistors (IGBTs).

Gallium nitride (GaN): GaN is a wide bandgap semiconductor material that offers superior performance compared to silicon in terms of efficiency, switching speed, and power density. It is used in devices such as power transistors, diodes, and rectifiers for high-frequency and high-power applications.

Silicon carbide (SiC): SiC is another wide bandgap semiconductor material that offers superior performance compared to silicon, especially at high temperatures and high voltages. It is used in devices such as Schottky diodes, MOSFETs, and thyristors for high-power and high-temperature applications.

Diamond: Diamond is an emerging power semiconductor material that offers the highest thermal conductivity, allowing for better heat dissipation and higher power density. It is still in the research and development stage, but has the potential to revolutionize power electronics technology.

Gallium arsenide (GaAs): GaAs is a high-performance semiconductor material that offers superior electron mobility and high-frequency performance. It is used in devices such as microwave transistors, amplifiers, and switches for telecommunications and defense applications.

Overall, power semiconductor materials play a critical role in the development of power electronics technology, and each material has its unique advantages and limitations depending on the application requirements.

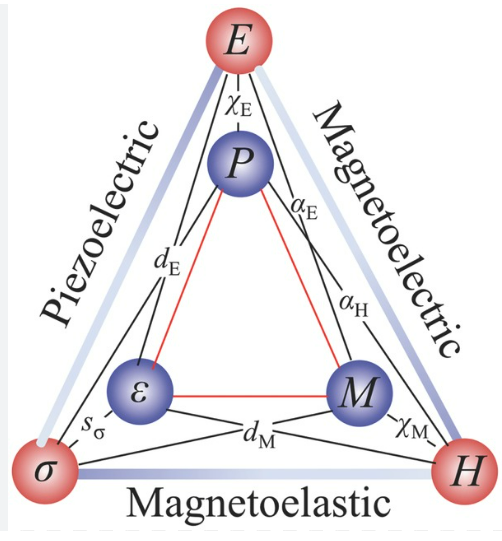

However, Gallium Oxide (Ga2O3) is another emerging wide bandgap semiconductor material that has shown promise for high-power and high-voltage applications. Ga2O3 has a much wider bandgap than silicon, GaN, and SiC, making it suitable for use in power devices that require high breakdown voltage, high current density, and low on-resistance. Importance of power semiconductor device for green energy can be easily understand from here. Fig 1 shows a brief relation of

Some of the potential feasibility and concerns of Ga2O3 as a power semiconductor.

High breakdown voltage: Ga2O3 has a high critical field strength, which allows it to withstand higher voltages without breakdown.

High current density: Ga2O3 has a high electron mobility, which allows it to carry more current than other wide bandgap materials.

Low on-resistance: Ga2O3 has a low specific on-resistance, which means that it can operate at lower voltages and consume less power.

Low cost: Ga2O3 is abundant and relatively low-cost compared to other wide bandgap materials.

Some of the potential applications of Ga2O3 power devices include high-voltage power supplies, electric vehicles, renewable energy systems, and high-power electronics for aerospace and defense.

Although Ga2O3 is still in the early stages of development, researchers are working on improving the quality of the material and developing new device structures to harness its full potential as a power semiconductor material. like any emerging semiconductor material, Gallium Oxide (Ga2O3) has some drawbacks that need to be addressed before it can be widely adopted in power electronics applications. Some of the major drawbacks of Ga2O3 include:

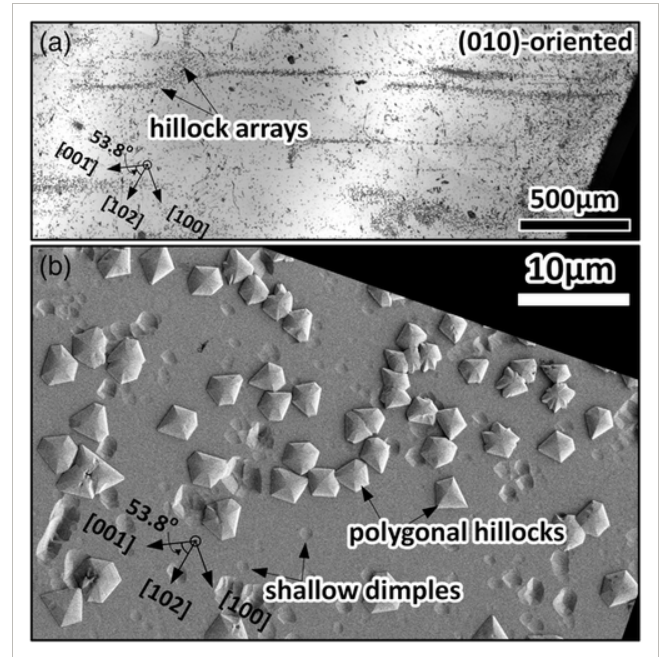

Crystal quality: Ga2O3 is a relatively new material, and its crystal quality is not yet as good as other wide bandgap materials such as SiC and GaN. Poor crystal quality can lead to defects and reduced performance in power devices.

Fabrication challenges: Ga2O3 is a complex material to fabricate into power devices, and the existing processes are not as mature as those for SiC and GaN. Developing reliable and scalable fabrication processes will be critical to the commercialization of Ga2O3 power devices.

Thermal conductivity: While Ga2O3 has a high breakdown voltage and low on-resistance, its thermal conductivity is lower than that of other wide bandgap materials. This can lead to higher operating temperatures and thermal management challenges in power devices.

Limited availability: While Ga2O3 is abundant, the supply of high-quality material for power electronics applications is limited. Developing cost-effective and scalable methods for producing high-quality Ga2O3 will be important for its widespread adoption.

Overall, while Ga2O3 has many potential advantages as a power semiconductor material, there are still several technical challenges that need to be overcome before it can be widely adopted in power electronics applications. Researchers are actively working on addressing these challenges to unlock the full potential of Ga2O3 as a power semiconductor material. Please find more information

here.